CTS 24V 12V Energy-Efficient 300Ah Lithium Ion Battery forRefrigerated Trucks

CTS 24V 12V Energy-Efficient 300Ah Lithium Ion Battery forRefrigerated Trucks

TypeCTS24V200AhCTS24V400AhCTS48V200AhCTS48V400AhNominal25.6V51.2VNominal Capacity200Ah400Ah200Ah400AhEnergy5120Wh10240Wh10240Wh19...

Description

CTS 24V 12V Energy-Efficient 300Ah Lithium Ion Battery forRefrigerated Trucks

Type |

CTS24V200Ah |

CTS24V400Ah |

CTS48V200Ah |

CTS48V400Ah |

|||

Nominal |

25.6V |

51.2V |

|||||

Nominal Capacity |

200Ah |

400Ah |

200Ah |

400Ah |

|||

Energy |

5120Wh |

10240Wh |

10240Wh |

19200Wh |

|||

Discharge current |

150A/300A |

150A/500A |

150A/400A |

150A/500A |

|||

Self Discharge |

<3%/Month |

||||||

Dimensions |

500*384*280mm |

800*384*280mm |

800*384*280mm |

800*384*390mm |

|||

Weight |

45kg |

95kg |

95kg |

170kg |

|||

Communication |

RS485/Bluetooh(Optional) |

||||||

Protection |

IP65 / Customize |

||||||

Operatiing Temp. |

-20 ~ 60 ℃ (-4 ~ 140℉) |

||||||

Lifetime |

≥6000+ times @80%DOD,0.5C/0.5C,25℃ |

||||||

Certification |

CE/MSDS/UN38.3 |

||||||

BMS |

Overcharge/Overdischarge Protection , Over Temperature Protection, Balance Current , Short Circuit Current Protection |

||||||

╣OEM Battery Parameters

CTS OEM 25.6v 300Ah Battery |

||

Battery Type |

Lifepo4 |

|

Total Energy |

7.68kWh |

|

Discharge Current |

80A cont |

|

Working Voltage |

20v to 29.2v |

|

Weight |

62kg |

|

Application |

Mobile solar tower |

|

CTS OEM 25.6v 100Ah Battery |

||

Battery Type |

Lifepo4 |

|

Total Energy |

2.56kWh |

|

Discharge Current |

100A cont |

|

Working Voltage |

20v to 29.2v |

|

Weight |

25kg |

|

Application |

Electric forklift |

|

CTS OEM 51.2v 200Ah Battery |

||

Battery Type |

Lifepo4 |

|

Total Energy |

10.24kWh |

|

Discharge Current |

100A cont |

|

Working Voltage |

40v to 58.4v |

|

Weight |

90kg |

|

Application |

Ice resurfacer |

|

CTS OEM 48v 50Ah Battery |

||

Battery Type |

NMC |

|

Total Energy |

2.34kWh |

|

Discharge Current |

50A cont |

|

Working Voltage |

39v to 54.6v |

|

Weight |

18kg |

|

Application |

AGV |

|

╣We can solve your concerns

1.BMS and Active Balance

CTS has an experienced BMS development team. Active balance can be selected according to the actual application of customers. It helps to balance each battery cell voltage, improve the charging and discharge efficiency and extend the battery lifespan.

2. We can design liquid cooling and heating system inside of the battery pack for you. This can make sure the battery works in the best condition.

3. Capable of communication protocol design and debugging CAN/ RS485/ RS232.

4. Capable of fast charge, 1.5C cont discharge and 3C peak discharge

7. CTS has its cooperated battery test laboratory. We will verify the battery DV / PV (design verification / production verification) stage in the laboratory to verify whether the design / production of the battery pack meets the design requirements. It includes temperature test, mechanical test, external environment simulation test, electrical safety test, battery performance test, abuse test and so on.

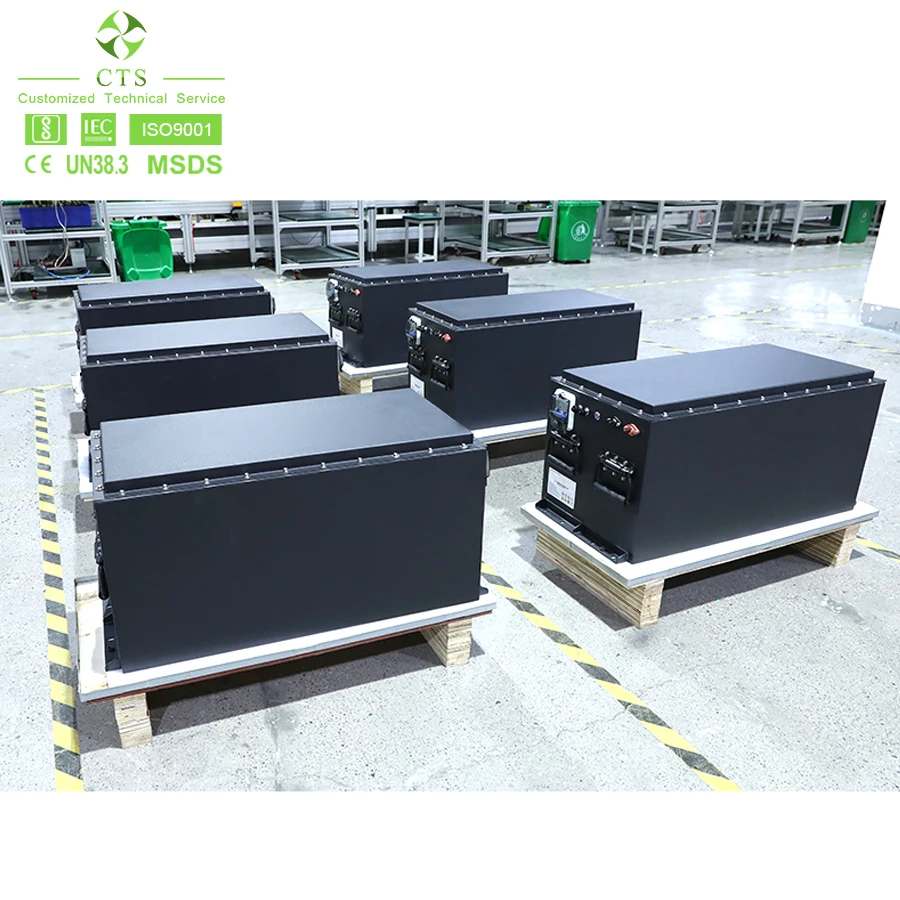

╣Production Details

From the battery cell to the battery pack, CTS controls every production link in strict accordance with the ISO9001 standard, arranges quality inspectors to check the process details to ensure the safety of the battery, and presents the best products to every customer.

╣Company Profile

╣Contact us

EN

EN