CTS Custom Lithium ion EV car battery 100kwh 500v 600v 200ah lifepo4 battery pack for electric tractor farm agricultural

CTS offers a customized lifepo4 battery for electric tractors in agricultural applications. With a voltage of 500v - 600v and a capacity of 200ah, providing 100kwh of power, this battery is engineered to meet the specific requirements of agricultural tractors. It offers reliable performance and long - lasting energy supply, ensuring efficient operation of electric tractors. With advanced technology and strict quality control, our battery is a top choice for enhancing the productivity and sustainability of agricultural tractors.

Description

500v200ah lithium battery pack for AGV

|

Parameters of 500v 200Ah Lifepo4 battery pack

|

|||

|

No.

|

Items

|

Technical requirement

|

Note

|

|

1

|

Battery type

|

500V200AH Lifepo4 Battery

|

|

|

2

|

Cell

|

3.2V 105AH LFP Prismatic cell

|

|

|

3

|

Energy

|

90.2kwh

|

at 23±2℃

|

|

4

|

Connections

|

154S2P

|

|

|

5

|

Working voltage

|

562V ~385V

|

|

|

6

|

Charging Voltage

|

562V±0.15V

|

|

|

7

|

Discharge cut-off Voltage

|

385V±0.3v

|

|

|

8

|

Standard Charging

|

80A

|

|

|

9

|

Max Charge Current

|

50A at0~10℃

80A at11~20℃ 80A at21~30℃ 80A at31~50℃ |

Temperature 0~50±2℃

|

|

10

|

Standard Discharging

|

200A

|

Temperature -20~55±2℃

|

|

11

|

Max Discharging Current

|

400A/10S

|

|

|

12

|

Communication

|

CAN bus

|

|

|

13

|

Liquid cooling

|

support

|

|

|

14

|

BMS

|

BMS+ Relay

|

|

|

15

|

Housing

|

IP67 Steel Case

|

|

|

16

|

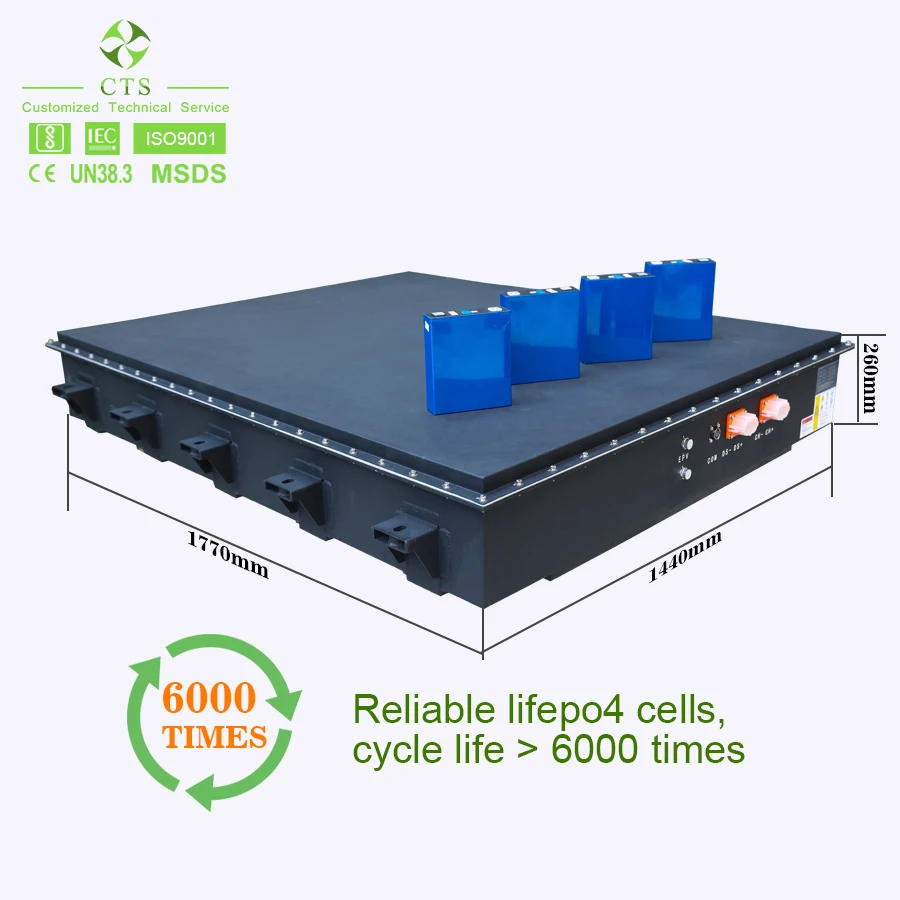

Dimension

|

1770*1436*207mm

|

adjustment

|

|

17

|

Working temperature

|

Discharging: -20 to 55℃ , Charging :0 to 55℃

|

|

|

18

|

Weight

|

About 900kg

|

|

|

19

|

2 meters charging & discharging and communication cable, CAN card x 1.

|

||

Title goes here.

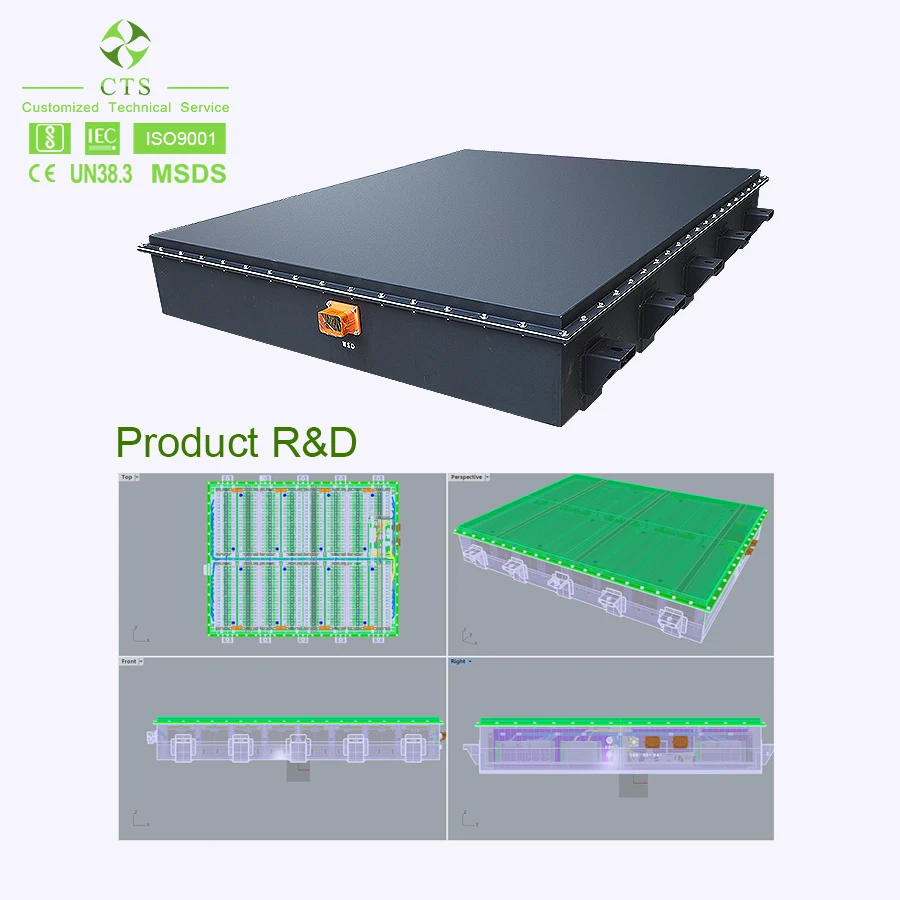

1. Design Capability

There are more than 20 experienced experts in our engineering and technical team, dealing with overall structural design from

cells to battery packs, battery system design, simulation design of cables and wires. We could also offering One-stop services by

providing motor, MCU, OBC and charging piles.

cells to battery packs, battery system design, simulation design of cables and wires. We could also offering One-stop services by

providing motor, MCU, OBC and charging piles.

2,Lightweight And Scalability

CTS systematically optimizes the cell design and electrical component selection. We select the lightest steel/aluminum alloy and

high-strength plastics,battery box and pack structure to reduce the volume and weight of the battery system combined with CAE

structural simulation analysis to ensure structural strength and improve energy density.

CTS uses standardized cells and BMS to build a 12V \ 24V \ 48V \ 72V battery modules. It can need different customer's

requirements by its excellent scalability to shorten the pack design cycle.

high-strength plastics,battery box and pack structure to reduce the volume and weight of the battery system combined with CAE

structural simulation analysis to ensure structural strength and improve energy density.

CTS uses standardized cells and BMS to build a 12V \ 24V \ 48V \ 72V battery modules. It can need different customer's

requirements by its excellent scalability to shorten the pack design cycle.

3,BMS And Active Balance

CTS has an experienced BMS development team. Our BMS uses passive balance by default. Active balance can be selected which can

modify BMS parameters on site according to the actual application of customers, such as CAN / RS485 communication protocol,

threshold parameters such as over / under voltage protection, high current protection, over / under temperature protection.

4,Thermal Management And Simulation Design

CTS has the capabilities of CFD simulation (Computational Fluid Dynamics) and CAE simulation (Computer Aided Engineering), and can

do thermal management simulation design and structural mechanics simulation design for the pack system. Air cooling system, liquid

heat and liquid cooling system, PI film heating, silica gel film heating are used in the thermal management design.

do thermal management simulation design and structural mechanics simulation design for the pack system. Air cooling system, liquid

heat and liquid cooling system, PI film heating, silica gel film heating are used in the thermal management design.

Test and Verification

CTS has its cooperated battery test laboratory. We will verify the battery DV / PV (design verification / production verification) stage in the laboratory to verify whether the design / production of the battery pack meets the design requirements. It includes temperature test, mechanical test, external environment simulation test, electrical safety test, battery performance test, abuse test and so on.

Our standard module widely used in the industry vehicle, Tunnel vehicle, large capacity AGV, Skyline crane. We have extensive experience in different market. lf you have any question please contact us, we will provide the proper solution for you!

Since 2011, CTS has focused on one-stop customization of lithium battery products such as electric vehicle batteries, large energy storage batteries, smart home storage batteries, high-end electric motorcycle batteries and so on.

We have more 30 types of cells, and could make OEM battery pack from 12v-800v, 10-1000ah, which can be used in electric vehicle, E-bike, UPS, energy storage system, telecommunication base station,E-scooter, E- tools,unmanned airplane, golf cart, fork lift,cleaning car , electric wheelchair, etc.

We has been pursuing quality policy of continuous innovation and improvement to meet customer's requirements. To realized full automation, we has introduced advanced foreign equipment and technology from Korea and Germany. To ensure the best quality, we has passed I S O 9 0 0 1 , I S O 1 4 0 0 1 and O H S A S 1 8 0 0 1 certifications.

We stick to the company concept of human orientation and efficient innovation and we welcome customization. So, lets join together to promote the development of renewable energy and friendly environment.

We have more 30 types of cells, and could make OEM battery pack from 12v-800v, 10-1000ah, which can be used in electric vehicle, E-bike, UPS, energy storage system, telecommunication base station,E-scooter, E- tools,unmanned airplane, golf cart, fork lift,cleaning car , electric wheelchair, etc.

We has been pursuing quality policy of continuous innovation and improvement to meet customer's requirements. To realized full automation, we has introduced advanced foreign equipment and technology from Korea and Germany. To ensure the best quality, we has passed I S O 9 0 0 1 , I S O 1 4 0 0 1 and O H S A S 1 8 0 0 1 certifications.

We stick to the company concept of human orientation and efficient innovation and we welcome customization. So, lets join together to promote the development of renewable energy and friendly environment.

EN

EN